Top Front Service LED Display Module Manufacturer In China

One-Minute Magic: Our Front-Access Revolution

- Save space and simplify installation

- Fast maintenance, efficient and convenient

- High stability and sealing

- Lightweight and beautiful

Why Choose Front Service LED Modules?

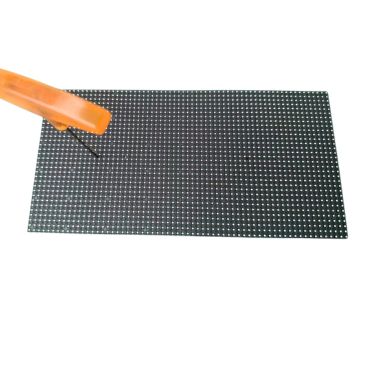

Front maintenance LED display module is a specially designed LED display unit. It does not need to be disassembled from the back of the LED screen. It can be installed, repaired or replaced directly through the front. It is suitable for scenes where space is limited or wall-mounted.

Front-Maintenance LED modules VS. Rear-Maintenance

| Feature | Front-Maintenance Module | Rear-Maintenance Module |

|---|---|---|

| Installation Space | Wall-mounted, no rear clearance | Requires ≥60cm rear access |

| Maintenance Speed | Front access, single-operator | Rear access, multi-person effort |

| Ideal Applications | Indoor & Outdoor fixed installs, retail | Outdoor large screens, rental |

| Cost Efficiency | Saves structural/upkeep costs | Higher long-term maintenance costs |

Advantages of front maintenance LED display module:

1. Space-Saving & Easy Installation

-

No rear maintenance access required: Modules can be serviced directly from the front, ideal for wall-mounted installations or space-constrained venues (e.g., shopping malls, elevator lobbies, indoor fixed installations).

-

Reduces overall project costs: Eliminates the need for deep structural supports, saving space and construction expenses.

2. Fast Maintenance & High Efficiency

-

Rotating lock design or Magnetic quick-release design: Tool-free, single-handed module removal; replacement takes <1 minute, minimizing downtime.

-

Single-point repairability: Individual faulty LEDs or driver ICs can be replaced without swapping the entire module, lowering maintenance costs.

3. Enhanced Stability & Durability

-

Open-frame design (no rear cover): Improves heat dissipation, reducing operating temperature by 10–15% and extending LED lifespan.

-

Dust-resistant and robust: Front-service mechanisms (e.g., latch locks) prevent connector loosening caused by frequent disassembly.

4. Slim Profile & Aesthetic Appeal

-

Ultra-thin cabinets (≤50mm): Perfect for high-end commercial spaces (luxury stores, showrooms) with seamless wall integration.

-

Seamless splicing: Die-cast aluminum or nano-coated bezels ensure superior flatness and wider viewing angles.

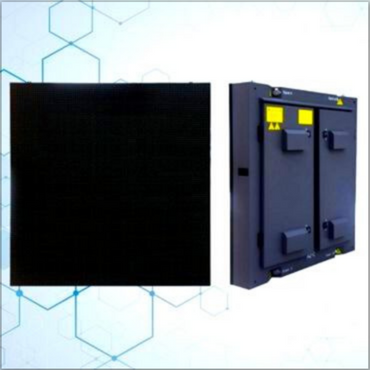

Professional Front Service LED Modules Manufacturer

Thinner. Smarter. Easier To Maintain

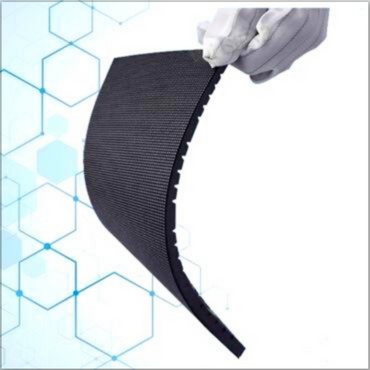

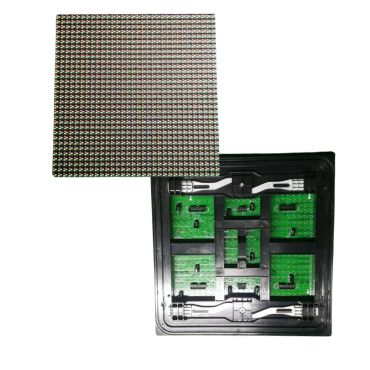

Currently there are three types of front maintenance LED modules: magnet adsorption type, screw type in front and quick disassembly of rotary lock buckle structure

Currently there are three types of front maintenance LED modules:

Magnet Adsorption Type

1. Quick installation & maintenance

✅ No tools required: The front service LED module is directly adsorbed on the box through a strong magnet, and can be disassembled and assembled by a single person with bare hands, greatly saving time and labor costs.

✅ Front maintenance friendly: It is especially suitable for scenes such as walls, embedded, etc. that cannot be maintained later. The faulty module can be replaced directly from the front.

2. High stability & anti-falling

✅ strong magnetic fixation: Use high magnetic materials such as neodymium magnets (NdFeB), which have strong adsorption, vibration resistance, and are not easy to shift or fall.

✅ Double insurance: Some high-end designs are equipped with snaps or screws to assist in fixing to ensure outdoor wind resistance and shock resistance.

3. Modular design, flexible expansion

✅ Plug and play: When a single front service LED module is damaged, it can be replaced separately quickly without affecting the overall screen operation (it is better to support hot-swap models).

✅ Lightweight cabinet: Magnetic suction structure simplifies the cabinet or even the cabinet-free design, reducing weight

Screw Type in Front and Quick

Although magnetic front service LED modules are better in installation convenience, The LED module design of screw locking or disassembly can be completed directly from the front of the screen. This type of module combines the stability of traditional screw fixation and the convenience of front maintenance. screw-fixed LED modules are still the first choice for many application scenarios due to their stability and reliability.

1. Convenient front maintenance does not require back space:

directly screw screws from the front to disassemble and install them, solving the pain points of inability to maintain after the wall and embedded installation.

Single-person quick operation: With a long-handled screwdriver or power tool, the maintenance efficiency is more than 50% higher than that of traditional post-maintenance.

2. High stability & vibration-resistant mechanical locking is more reliable:

screw fixing is stronger than magnetic suction wind pressure and vibration resistance, and is suitable for outdoor high altitudes (such as building advertising screens) or traffic vibration environments (such as subway stations).

Stay flat for a long time: the pre-pressure of the screw can be adjusted to avoid splicing gaps in the module due to temperature difference deformation.

3. The sealing is better than the magnetic suction type.

It is better to have waterproof and dustproof: the screw is pressed with waterproof adhesive strips, which can easily achieve IP65/IP68 protection level, suitable for rainy and high humidity areas. ️

Moisture-proof and corrosion-proof: Aluminum alloy cabinet + stainless steel screws are more resistant to salt spray corrosion than magnetic suction modules (neodymium magnets are afraid of oxidation) (such as seaside scenes).

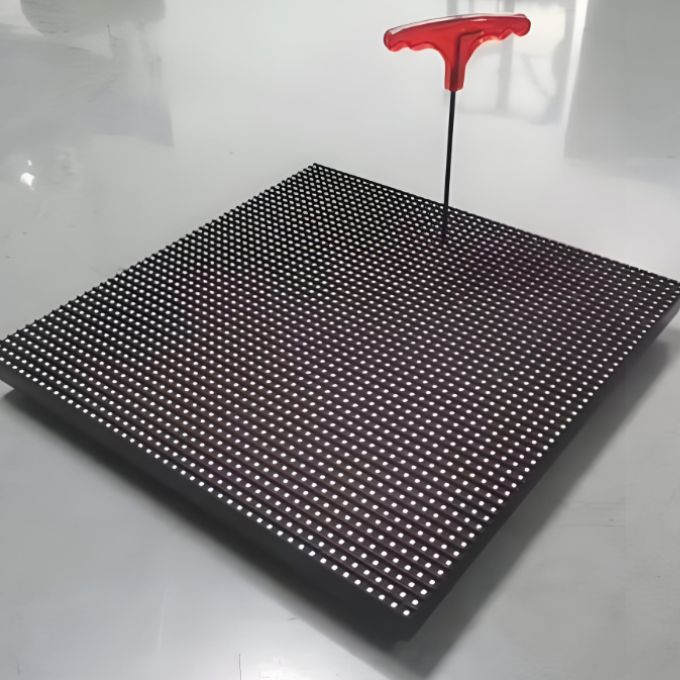

Rotary Lock Buckle Structure

Front-access Quick-release Locking Mechanism is a popular front service LED module fixing method in recent years, combining the convenience of magnetic absorption and the stability of screw fixing.

1. Quickly disassemble and install, double maintenance efficiency

Complete with one plug and one turn: Insert the Allen wrench from the front of the LED display and rotate it, you can remove or install the LED module, which is more than 3 times faster than the screw fixing.

Support hot swapping: Some high-end models allow continuous power replacement, which is especially suitable for live broadcasts, stages and other occasions where display cannot be interrupted.

2. Front maintenance is friendly, space adaptability is strong

the back space is ignored: operate directly from the front to perfectly solve the maintenance problems of wall-mounted and embedded installations.

LED Module replacement separately: In case of failure, only the problematic front maintenance LED module needs to be removed, which does not affect the peripheral units and reduces maintenance costs.

3. High-precision splicing, good picture consistency

self-alignment design: the lock buckle has a positioning guide column to ensure automatic calibration during installation, avoiding pixel misalignment or light and dark lines. Zero gap fit: The mechanical locking force is uniform, and the screen can still be kept flat and warped for a long time (better than pure magnetic suction and screw types).

Give You The Most Reasonabler Front Service LED display Solution

Related Product

What is the difference between the front maintenance LED module and the traditional rear maintenance LED module?

Front maintenance: Disassemble from the front, saving back space, suitable for wall-mounted installation.

Rear maintenance: It needs to be operated from the back, and maintenance channels at least 80cm are required.

Usually, the magnetic, snap-on or screw-fixing design is used, and the module can be removed by unlocking it from the front with a special tool (such as a suction cup).

The high-quality LED front maintenance module can still reach IP65 protection level, but the seal strips and interfaces need to be checked regularly to prevent aging and water seepage.

Power off;

use suction cup or tool to adsorb the module;

unlock the lock/magnetic suction device;

unplug the power/signal cable, replace the new module and rewire the lock.

All pre-hard connection maintenance LED modules support hot-swap (continuous power replacement). Because of the power cord, the wired soft-connected LED module is powered off.

Remove and place the LED lamps to avoid damage and dropping, and pulling the peripheral cables; use anti-static gloves to prevent electrostatic breakdown of the LED chip.

It is usually 10%-20% more expensive than the rear maintenance LED module, but it saves installation space and labor costs, and has a higher long-term cost-effectiveness.

Shopping mall LED advertising screens, running text LED display for Storefront Signs, exterior walls and other scenes where back space cannot be reserved.