All Kinds Of DIP LED Display Modules Manufacturer

TS is a leading manufacturer of DIP LED Screen Modules in China.

- Over 14 years of experience in the production of Dip LED display modules

- High brightness

- Strong stability

- Energy saving

- 5years warranty

- Life-Long Maintenance

Why We Still Insist On Produce DIP LED Modules?

1. Good quality.

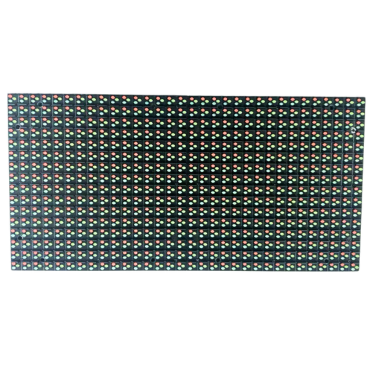

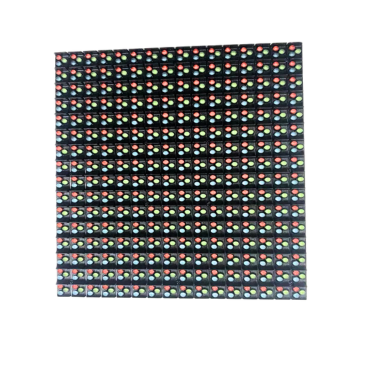

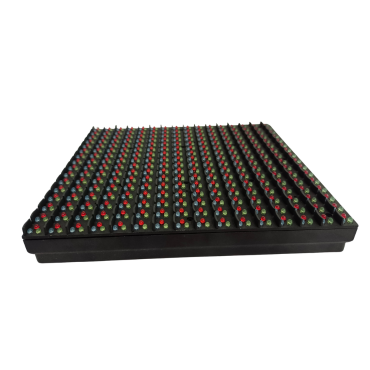

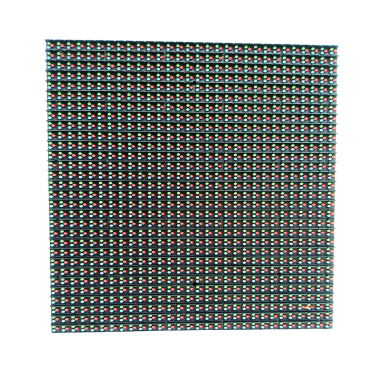

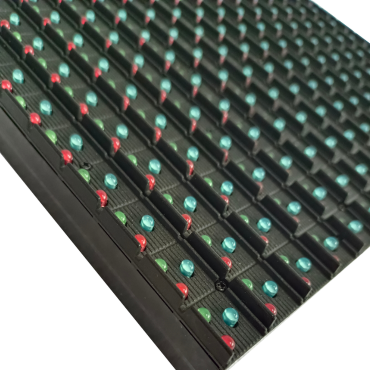

The DIP 3 colors LED module consists of 3 independent LED lamp beads to form a pixel. It has high brightness, good heat dissipation, and high contrast. The loss of a single color lamp bead will not cause the entire pixel to go out of control.

The lamp board and IC driver board are designed separately, which greatly reduces the heat of the IC. The direct-plugged LED display and module have a longer life. The SMD LED module lamp beads and IC are on a PCB board, and the heat is very large. This leads to reduced lamp bead life and white balance color distortion.

The lifespan of P10 direct-plug LED modules is generally at least 1 times that of SMD LED modules, and the power of direct-plug LED displays is also significantly energy-saving by about 50%.

2. Repair and Replacement DIP LED Screens and Modules

DIP LED displays have a 20-year history. Before 2014, P10 DIP LED modules were used to assemble LED displays. Nowadays, 99% of LED display factories only produce SMD LED displays and COB LED displays. In the past, When the installed DIP LED display was faulty or damaged, repair and replacement were a very big problem for end users. TS has a full range of DIP LED display modules, such as P10, P16, P20, P25, etc. Helping users solve the problem of not being able to find P10 DIP LED module repairs and replacements

RGB Full color DIP LED Display Module List

RGB 3 color DIP LED Modules Factory.

DIP Single color LED Module

Pixel pitch(mm):10MM

Size:320*160mm

LED TYPE:546 Red

Scan:1/4

PCB:706/806

Pixel pitch(mm):10MM

Size:320*160mm

LED TYPE:546 Green

Scan:1/4

PCB:706/806

Pixel pitch(mm):10MM

Size:320*160mm

LED TYPE:546 Yellow

Scan:1/4

PCB:706/806

Pixel pitch(mm):10MM

Size:320*160mm

LED TYPE:546 white

Scan:1/4

PCB:706/806

Pixel pitch(mm):10MM

Size:320*160mm

LED TYPE:546 blue

Scan:1/4

PCB:706/806

Pixel pitch(mm):10MM

Size:320*160mm

LED TYPE:546 RED+Green

Scan:1/4

PCB:706/806

Pixel pitch(mm):12.5MM

Size:200*200mm\400*200mm

LED TYPE:546 Amber\Red

Scan:1/4

Pixel pitch(mm):16MM

Size:256*256mm/256*128mm

LED TYPE:546 R/G/B/W/P

Scan:1/1

Pixel pitch(mm):13.4MM

Size:416*214mm

LED TYPE:546 RED+AMBER

Scan:1/4

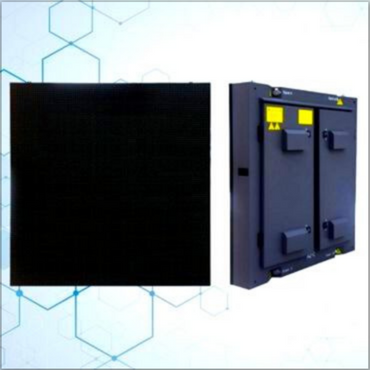

Outdoor Front service DIP LED Display Modules

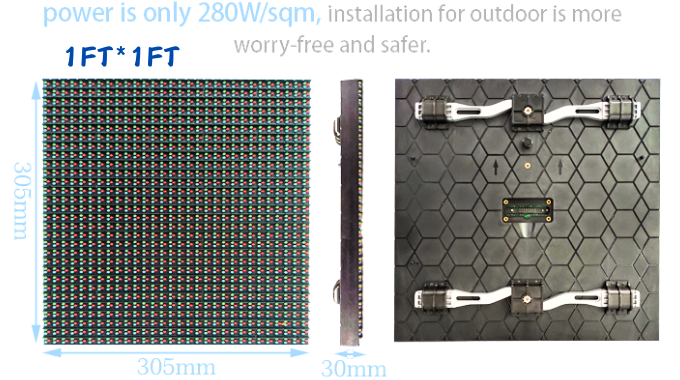

TS has sizes 320*320MM and 1FT*1FT Front service LED Display serial.

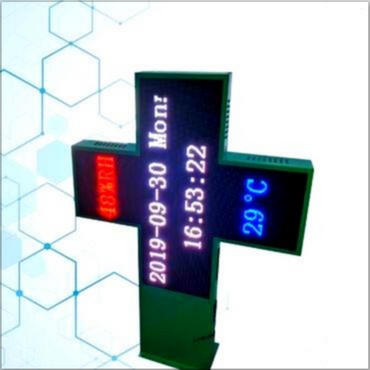

The front service LED Module is good for small LED screens, like LED screens for machines, LED cross, and digital LED Signs.

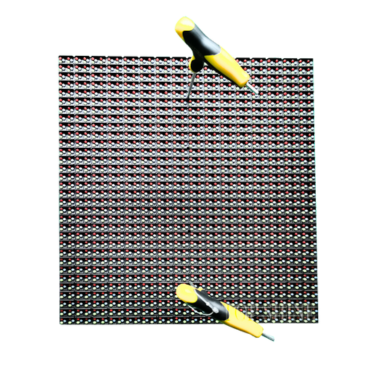

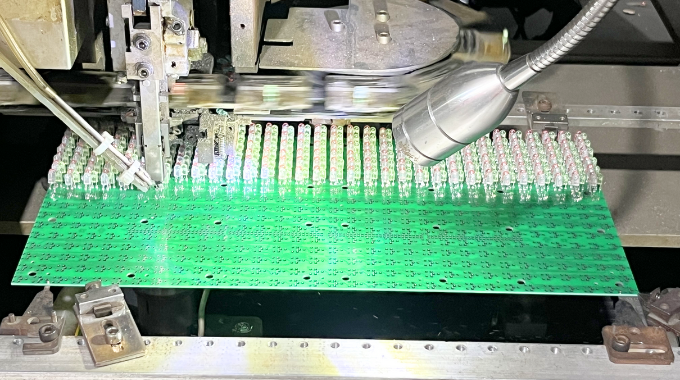

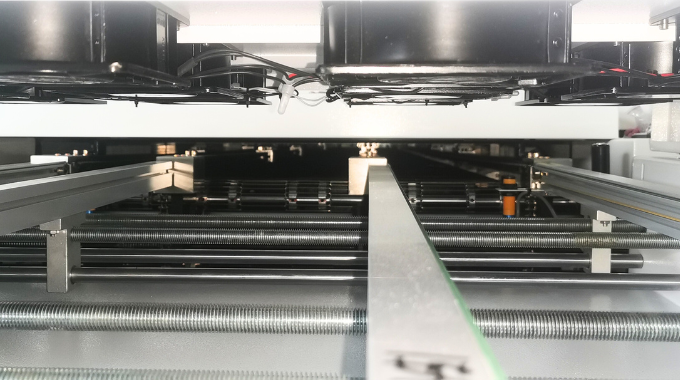

Automatic LED Lamp Insertion Machine

This DIP Lamp insertion machine has a stable mechanical structure and operation panel, which is convenient for users to operate and monitor the working status of the machine. At the same time, to improve production efficiency, an automated feeding and lamp insertion system is adopted to insert the DIP LED Lamp into the PCB board of the DIP LED module more accurately and quickly.

Machine insertion can ensure the consistency of the direction of the lamps of the DIP LED module. Therefore, after wave soldering, the vertical deviation of the lamps of the DIP LED module is small, and the overall DIP LED display has a unified luminous angle, achieving perfect Display effect and white balance.

Industrial Grade Wave Soldering

1. Good welding quality: Since the flux stays at the contact point for a short time, it can quickly heat and cool the connection part, thus ensuring good welding quality of all direct-plug LED modules.

2. Efficient production: Wave soldering can realize automated operations, improve production efficiency, reduce labor costs, and achieve cost-effective in-line LED displays and modules.

3. Strong stability: The equipment is imported from Japan, and the stability of the product is extremely high, ensuring that the components of each direct-plug LED module are fully welded.

4. Low-temperature welding: Compared with traditional hot-pressure welding and arc welding, wave soldering has a lower temperature, which reduces the impact of thermal stress on the material and improves the DIP LED Module’s durability.

5. Convenient non-destructive testing: During the wave soldering process, the welding quality can be judged by observing the color, shape, and other characteristics of the solder joints, which facilitates non-destructive testing for each DIP LED module.

Original Design

TS PCB Design

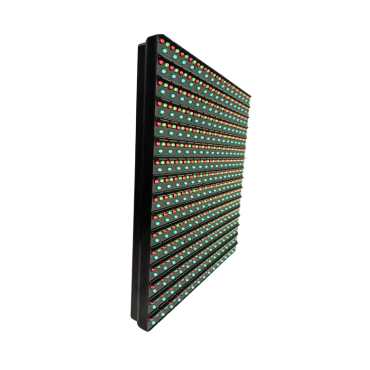

Reasonably arrange the positions of various components on the PCB to ensure that the signal transmission path is unobstructed and avoid mutual interference. At the same time, consider the heat dissipation problem of the DIP LED Module and rationally design the heat dissipation holes and heat sink to ensure that the temperature of the DIP LED module will not be too high during normal operation.

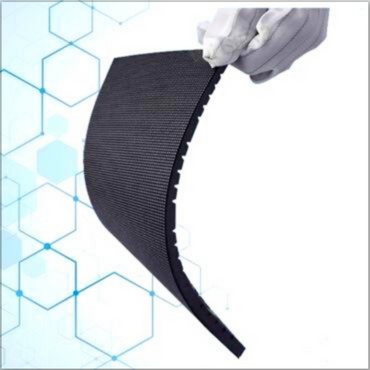

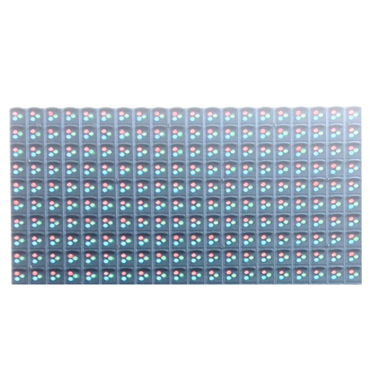

Plastic bottom case design

The material of the plastic bottom case is V0-level fireproof PC plus lead material, which ensures fire protection while ensuring strength and toughness. The size of the plastic bottom case is neither large nor small, ensuring the accuracy and endurance of the DIP LED module splicing. The mask uses an anti-glare brim with a sunshade to improve brightness and contrast.

Advantages of TS Outdoor DIP LED Modules?

The maximum power of the DIP P10 P16 general outdoor advertising screen per square meter is less than 400W, and the average power is about 100W. The low power not only reduces the power consumption of the LED advertising screen but also reduces the heat generation of the LED display screen while running at low power, extending the LED display life. The service life also reduces operating costs.

We use the industry’s top materials to make DIP LED Modules, and use high-brightness and high-airtight DIP LED LAMPS to ensure that they can be used outdoors for a long time and are not affected by sunlight and harsh environments, which may cause discoloration, moisture, attenuation, etc. Breakdown, V0 waterproof grade housing, and pure copper connectors.

TS’s design team has more than 15 years of experience in DIP LED module design. All DIP LED modules use 1.6MM thick double-sided PCB boards. By optimizing the PCB layout and routing methods, the power supply voltage and load of each IC and LED LAMP can be improved. Hot spots should be stabilized and averaged. Make the white balance and color of the entire DIP LED module purer and more stable

Outdoor LED Modules Datasheet

- 3color DIP LED Modules

- Outdoor DIP LED Panels

| Fixed-DIP-Outdoor | TFD-10 | TFD-10.16 | TFD-15.24 | TFD-16 |

| Pixel pitch(mm) | 10 | 10.16 | 15.24 | 16 |

| Pixel Density(dot/m2) | 10000 | 96875 | 4305 | 3906 |

| LED Type | DIP346 | DIP346 | DIP346 | DIP346 |

| Module Size(W x H x D)mm | 160×160-320 x 160-320×320 | 1FTx 1FT 304.8MM*304.8MM | 1FTx 1FT 304.8MM*304.8MM | 256 x 128/256x 256 320×320 |

| Module resolution(W x H) | 16×16-32 x 16 | 30 x 30 | 20 x 20 | 16x 8/16×16/20×20 |

| Module Weight(Kg) | 1.7 | 2.2 | 2.2 | 1 |

| Power Consumption per Module(w) | 30 | 35 | 35 | 18/35 |

| Diver Mode(Scan) | 1/4 | 1/5 | 1 | 1 |

| Brightness(cd/m2) | 8500-10000 | 8500-10000 | 8500-10000 | 8500 |

| Grey Scale(bits) | 16 | 16 | 16 | 16 |

| Refresh Rate(Hz) | ≥1,920 | ≥1,920 | ≥1,920 | ≥1,920 |

| Cabinet Size(W x H x D)mm | 960 x 960 x150 | 4FT x 3FT x 3FT | 4FT x 3FT x 3FT | 1024 x 1024 x 150 |

| Cabinet Weight(Kg/m2) | 46 | 40 | 40 | 46 |

| Max Power Consumption(W/m2) | 400 | 600 | 600 | 500 |

| Average Power Consumption(W/m2) | 120 | 200 | 200 | 150 |

| View Angle(H°/V°) | 160/100 | 160/100 | 160/100 | 160/100 |

| Mini View Distance(m) | 10 | 10 | 12 | 16 |

| Operating Use Temperature(℃) | -20℃~60℃ | |||

| Storage Use Temperature(℃) | -20℃~60℃ | |||

| Input Voltage(V) | 100~240V | |||

| Input Power Frequency(Hz) | 50Hz~60Hz | |||

| Failure Rate | <1/100,1000 | |||

| Signal Input Format | SDI, RGBHV,YUV,YC,Composite,HDMI,DVI,SD/HD-SDI etc. | |||

| Life Time(hrs) | 100000 | |||

| IP Level(front/rear) | IP65/IP56 | |||

| Fixed-DIP-Outdoor | TFD-10 | TFD-12 | TFD-12.5 | TFD-16 | TFD-20 | TFD-25 |

| Pixel pitch(mm) | 10 | 12 | 16 | 16 | 5 | 6 |

| Pixel Density(dot/m2) | 10000 | 6944 | 6400 | 3906 | 2500 | 1600 |

| LED Type | DIP346 | DIP346 | DIP346 | DIP346 | DIP346 | DIP346 |

| Module Size(W x H x D)mm | 160×160-320 x 160-320×320 | 192x 192 | 200 x 200 | 256 x 128/256x 256 | 320 x 160 320x 320 | 200 x 200 |

| Module resolution(W x H) | 16×16-32 x 16 | 16 x16 | 16 x16 | 16x 8/16×16 | 16 x 8 | 8 x 8 |

| Module Weight(Kg) | 1.7 | 0.8 | 0.85 | 1 | 0.8 | 0.5 |

| Power Consumption per Module(w) | 30 | 15 | 15 | 18/35 | 20 | 12 |

| Diver Mode(Scan) | 1/4 | 1/4 | 1/4 | Static | Static | Static |

| Brightness(cd/m2) | 8500 | 8000 | 8000 | 8500 | 7000 | 7000 |

| Grey Scale(bits) | 16 | 16 | 16 | 16 | 16 | 16 |

| Refresh Rate(Hz) | ≥1,920 | ≥1,920 | ≥1,920 | ≥1,920 | ≥1,920 | ≥1,920 |

| Cabinet Size(W x H x D)mm | 960 x 960 x150 | 960 x 960 x150 | 1000 x 1000 x150 | 1024 x 1024 x 150 | 960 x 960 x150 | 1000 x 1000 x150 |

| Cabinet Weight(Kg/m2) | 46 | 46 | 46 | 46 | 46 | 46 |

| Max Power Consumption(W/m2) | 400 | 600 | 600 | 500 | 400 | 300 |

| Average Power Consumption(W/m2) | 120 | 200 | 200 | 150 | 150 | 100 |

| View Angle(H°/V°) | 120/80 | 120/80 | 120/80 | 120/80 | 120/80 | 120/80 |

| Mini View Distance(m) | 10 | 12 | 12 | 16 | 20 | 25 |

| Operating Use Temperature(℃) | -20℃~60℃ | |||||

| Storage Use Temperature(℃) | -20℃~60℃ | |||||

| Input Voltage(V) | 100~240V | |||||

| Input Power Frequency(Hz) | 50Hz~60Hz | |||||

| Failure Rate | <1/100,1000 | |||||

| Signal Input Format | SDI, RGBHV,YUV,YC,Composite,HDMI,DVI,SD/HD-SDI etc. | |||||

| Life Time(hrs) | 100000 | |||||

| IP Level(front/rear) | IP65/IP56 | |||||

Related Product

TOP3 DIP LED modules Manufacturer in China

All Kinds of DIP LED modules factory.

1. The Holes of the DIP LED Screen Module, must be the same, then can be installed to the DIP LED Screen cabinet.

2. The PCB Design of the DIP LED panel must be the same, then can be working together.

3. The order of 3 color LED Lamp must be the same, then the color can be the same.

4. The size and thickness of the DIP LED Module Must be the same.