Front maintenance LED screen:

Installation method: Typically uses magnetic or quick-lock mounting. The modules can be directly attached to the cabinet from the front or easily removed.

Cabinet structure: The cabinet is thicker and more robust, requiring internal space to be left for maintenance access, and sometimes a dedicated maintenance channel is designed.

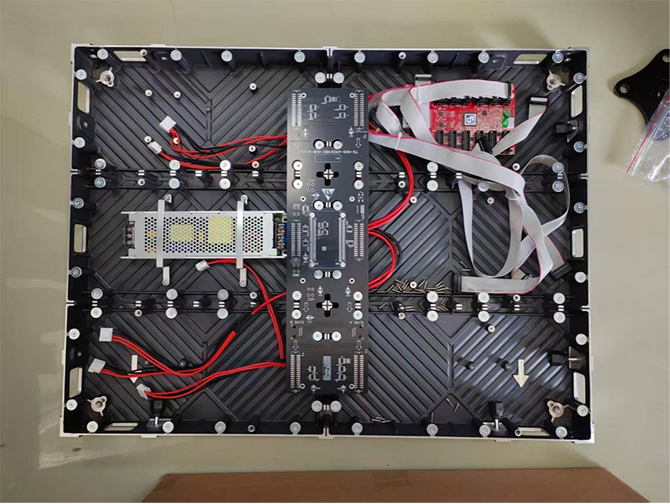

Rear maintenance LED screen :

Installation method: The modules are fixed to the cabinet using screws or other methods, and the cabinet is then fixed to the wall or steel structure.

Cabinet structure: They are generally thinner because they don’t need to accommodate people entering.

Advantages and Disadvantages of Front Maintenance

Advantages:

(1) Space-saving: This is the biggest advantage. The display screen can be mounted flush against the wall, embedded in the wall, or installed behind a glass display case, making it ideal for indoor spaces with limited space (such as shopping malls, lobbies, and elevator entrances).

(2) Flexible installation: It requires less demanding requirements for the installation background wall, as there is no need to consider access from the back.

(3) Convenient and fast maintenance: A single person can replace modules from the front. A suction cup tool is used to remove the faulty module and replace it with a new one, eliminating the need to climb behind the screen, resulting in higher safety and efficiency.

(4) Aesthetically pleasing: There is no need to leave space for a back door around the screen, resulting in a more integrated and streamlined appearance.

Disadvantages:

(1) High requirements for module precision: Magnetic mounting requires extremely high dimensional accuracy of the modules to ensure a flat and seamless splicing effect.

(2) Relatively high cost: The manufacturing process for magnetic modules and their corresponding cabinets is more complex, and the initial cost is usually higher than that of rear-maintenance cabinets.

(3) Affects viewing during maintenance: Maintenance must be performed from the front, which will temporarily obstruct the view, making it suitable for scenarios that do not require 24/7 uninterrupted use.

(4) Typically used indoors: Due to the lightweight and thin structure and waterproofing considerations, front-maintenance designs are mostly found in indoor screens, with fewer outdoor applications (but there are also outdoor front-maintenance designs).

Advantages and Disadvantages of Rear Maintenance

Advantages:

(1) Robust and stable structure: Uses screw fastening for a more secure connection, resulting in better wind resistance and overall strength, making it the standard choice for outdoor LED displays.

(2) Relatively low cost: Traditional manufacturing processes are mature, resulting in lower manufacturing costs for the cabinet and modules.

(3) Maintenance does not affect front viewing: Repair work is performed from the back, allowing the front display to function normally (unless power needs to be cut), suitable for live broadcasts, stage performances, and other scenarios where uninterrupted display is required.

(4) Good heat dissipation: The large open space on the back of the screen facilitates better air circulation and heat dissipation.

Disadvantages:

(1) Requires maintenance space: This is the biggest disadvantage. The back of the screen cannot be sealed, requiring a passage of at least 60cm to 1 meter wide, which is often impossible in many indoor venues.

(2) Inconvenient maintenance: Maintenance personnel need to access the back of the screen, where the space may be narrow, dark, and hot, making operation difficult and usually requiring two people (one to disassemble from the back, and one to observe the display effect from the front).

(3) Requires specific installation environment: The maintenance passage and access routes must be planned in advance, sometimes requiring the construction of a dedicated steel structure maintenance corridor.