一. Pre installation preparation and site survey:

1) Site survey:

①Outdoor Led Screens Installation location: Determine whether to install on a wall, roof, or freestanding column. Assess the wall structure load bearing wall, hollow brick wall, or foundation conditions.

②Viewing angle and distance: Determine the viewing direction and distance of the primary audience to determine the installation height and tilt angle of the display screen.

③Environmental factors: Check for obstructions, direct sunlight which affects display quality, and areas prone to water accumulation.

④Safety assessment: Ensure that the installation location does not pose a threat to people and property.

2)Design and planning:

①Structural Design of Outdoor Led Screens: Based on the size and weight of the display screen, as well as local natural conditions such as maximum wind load and snow load, professional engineers design and install the structure such as steel frame and columns to ensure sufficient strength and stability.

②Electrical planning: Plan the routing of power lines and signal lines to ensure separation from high-voltage and low-voltage wiring, and design the locations of distribution boxes and network equipment.

③Foundation or Embedded Parts Construction if required: For column mounted installations, a concrete foundation needs to be poured in advance and anchor bolts need to be pre embedded. For wall mounted installations, high strength chemical bolts or embedded steel plates need to be inserted into the load bearing structure.

3)Materials and tools preparation:

①Display enclosure: The waterproof rating usually needs to reach IP65 or higher.

②Installation structure: Custom made steel frame, columns.

③Electrical equipment: distribution boxes, circuit breakers, contactors, power cords, network cables, optical fibers.

④Installation tools: crane or scaffolding, welding machine, electric drill, wrench, level, laser rangefinder.

二. On site installation and construction:

4)Installation structure construction:

①The installation structure involves securely installing the prefabricated steel structure onto the wall or foundation according to the design drawings.

②Use a level to ensure the structure is perfectly horizontal and vertical, and all welds and connections must be secure and reliable, this is the foundation of safety.

5)Display cabinet installation:

①Cranes are typically used to lift the boxes one by one onto the steel structure.

②The housings are aligned using precision positioning pins and then secured with screws.

③During installation, continuous adjustments are needed to ensure that the entire display screen is flat, seamless, and without any steps.

6)Wiring and connection of Outdoor Led Screens:

①Power cables: Run cables from the distribution box to each power input on the back of the display screen according to the design, be sure to label the cables and follow the three phase balance principle.

②Signal line: Starting from the control computer sending card, it is connected to the first receiving card of the display screen via a network cable or fiber optic cable, and then the cabinets are cascaded together via network cables.

③All outdoor cables must be waterproof, and waterproof junction boxes and O rings must be used at the connection points to ensure a tight seal.

三. Debugging and acceptance:

7)Power on test:

①After the wiring is completed, carefully check all the lines and only turn on the power for the first time after confirming that everything is correct.

②First turn on the control device, then turn on the display screen power, and observe if there are any abnormalities such as smoke or unusual noises.

8)System debugging:

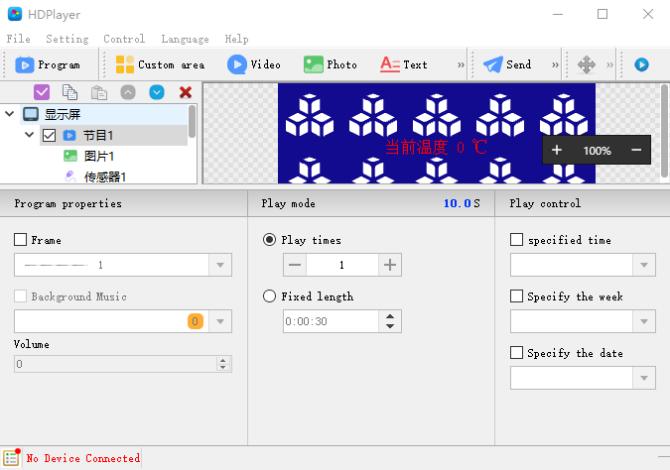

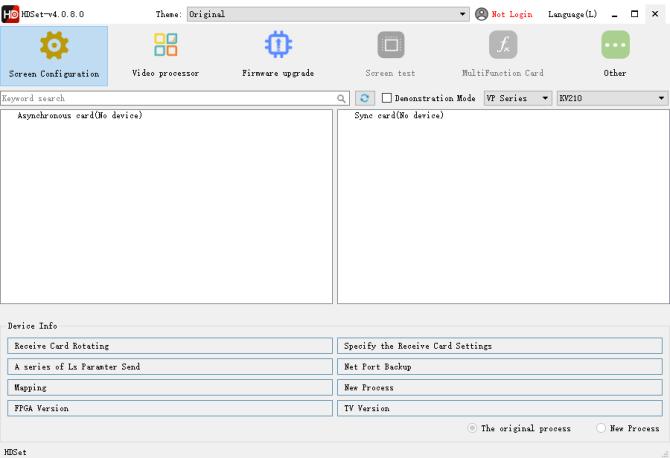

①Software connection: Connect the control computer to the display screen and install the control software.

②Parameter settings: Set basic parameters such as screen size, resolution, and scanning method.

③Pixel by-pixel calibration: Fine tuning the brightness and color of each led pixel to ensure uniform color across the entire screen, this is crucial for high end displays.

④White balance correction: Adjusts the mixing ratio of red, green, and blue light to make white appear pure.

⑤Content playback test: Play solid color images, videos, text, etc. of various colors to check for dead pixels, constantly lit or unlit pixels, and whether the colors are normal.

四. Important Precautions and Safety Regulations:

①Safety First: Safety regulations for working at heights and electrical work must be followed throughout the entire process, construction workers must wear safety helmets and safety belts.

②Professional Qualifications: The installation team must possess professional knowledge and construction qualifications related to steel structures and electrical systems.

③Wind and earthquake resistance: The structural design must meet or even exceed the local basic wind pressure and seismic fortification requirements.

④Strict waterproofing: The outdoor environment is harsh, and even the slightest waterproofing lapse can cause short circuits in internal components, resulting in huge losses.

⑤Heat dissipation design: Outdoor displays generate a lot of heat when they are working, so they must have a good heat dissipation system such as air conditioners and fans to ensure that the internal temperature of the cabinet is within a reasonable range.

⑥Lightning protection grounding: An independent lightning protection grounding system must be installed to discharge any lightning current that may be introduced into the ground.

⑦Compliance: Before installation, you need to understand the approval requirements of local urban management, planning and other departments for outdoor advertising and complete the relevant procedures.