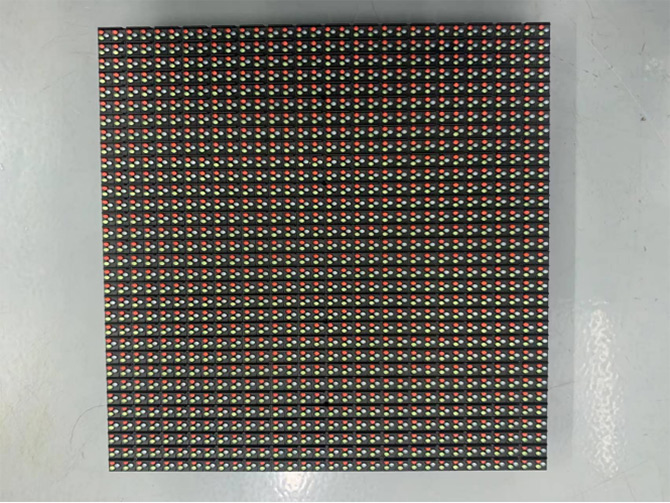

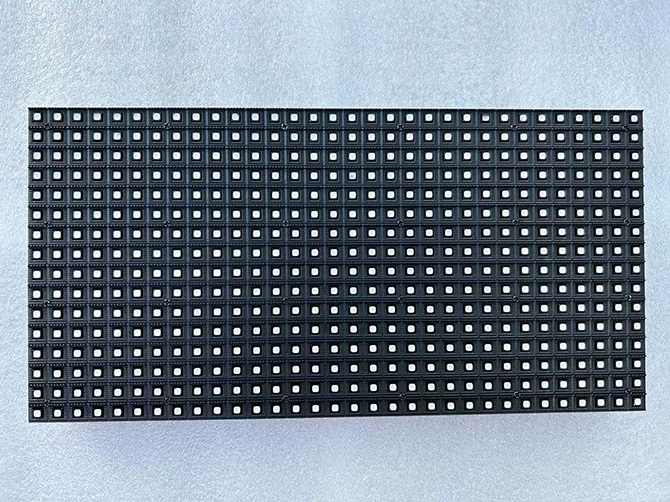

An full color LED display screen consists of modules, power supplies, receiving cards, and cabinets. There are two types of module models: one is a DIP module, and the other is an Module LED CMS.

First, we can distinguish them based on the choice of raw materials for the lamp.

DIP LED Module, the lamp is cylindrical in shape, with a hemispherical protrusion at the top. By inserting the LED chip’s leads into holes on the printed circuit board (PCB) for soldering.

It employs a through-hole packaging technology, requiring robust fixation and insulation for the long leads. Consequently, its structure is more substantial to withstand the physical stresses encountered during insertion/removal and wave soldering processes.

Due to structural reasons, DIP LED modules are mainly used for P10, P16, P20 and other pixel pitches.

The LED display screen it makes is mainly used in outdoor products.

SMD LED Module, the lamp is either cube-shaped or rectangular in form, and is soldered directly to the pads on the PCB board via its lamp.

It employs surface mount technology (SMT), with the package design prioritizing extreme thinness and flatness. Its structure facilitates stable pickup by the vacuum nozzle of the placement machine and ensures tight contact with the PCB surface during reflow soldering, resulting in reliable solder joints.

SMD LED module has a flexible structure and an adjustable metal bracket. The indoor range is from P1.95 to P10, and the outdoor range is from P2.5 to P10. It has a variety of types and is widely used, such as indoor fixed products, outdoor billboard products, pole LED display screens, modules LED flexibles, and naked-eye 3D creative LED display screen products.

The performance differences between DIP modules and SMD modules lie in three aspects: brightness, image display effect and service life.

1.Brightness

When the pixel pitch between the two products is the same, the brightness of DIP LED display screen is generally greater than that of the SMD LED display screen.

2. Image display effect

DIP lamps are mounted onto modules, creating an uneven surface. Combined with their full-emitting surface characteristic, DIP LED displays produce a less uniform and smooth visual effect compared to SMD LED displays when illuminated.

3. Service life.

DIP lamp chips are generally larger than SMD lamp chips. In practical use, DIP LED displays have a longer service life than SMD LED displays, but correspondingly, they are also more expensive.

And SMD module features high brightness, wide viewing angle, and excellent stability. DIP module offers high stability and superior weather resistance, making it particularly suitable for harsh environments such as outdoor applications.