The connection methods of LED display screens are mainly divided into two types: “soft connection” and “hard connection”.

To begin with, soft connection usually refers to the connection between the modules or cabinets of the LED display screen through external signal lines and power lines.

However, this method requires connecting the lines one by one during installation, which is often cumbersome.

On the other hand, hard connection is to integrate all the connection lines inside the cabinet or module, reduce wire connection, and be clean and simple.

LED hard connection technology is an innovative connection method in the field of LED display screens.

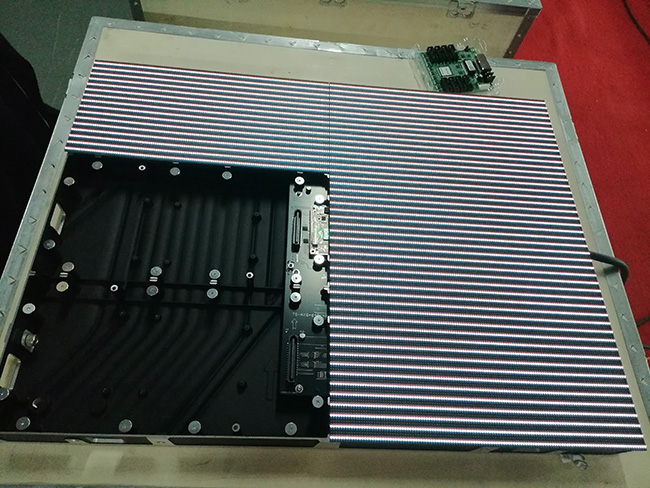

Top Shine- indoor p2.5 640*480mm hard connection LED display, it has a private version design in terms of modules.

1. The IC layout is more reasonable, which improves the operating efficiency and stability of the system;

2. The current is uniform, high-quality lamps are used, and the color temperature is highly consistent;

3. The interface adopts a gold-plated design, which has the effects of high conductivity, corrosion resistance, low loss and strong durability.

Hard connection LED display, the module thickness is thinner than the conventional bottom shell module.

And the aluminum cabinet is lighter than the traditional iron cabinet, which is convenient for transportation and installation.

The aluminum material also has good thermal conductivity and better heat dissipation.

Multiple installation methods

No maintenance channel is required behind the screen, and it supports wall installation, which greatly saves space.

It supports multiple installation methods, including seat installation, hanging installation, wall installation, floor installation, etc.

It brings many significant benefits. Its main advantages are:

1. Simplify the installation process

The hard connection design of the LED cabinet no longer requires connecting the lines one by one during installation.

The installer only needs to connect the modules or cabinets through the interface to complete the splicing, which greatly simplifies the installation process and shortens the installation time.

2. Improve maintenance efficiency

The LED cabinet with a hard connection structure has integrated lines, so when a fault occurs, the problem can be located and maintained more quickly.

This design reduces after-sales problems caused by line failures, and also reduces the difficulty and cost of after-sales maintenance.

3. Improved aesthetics

Traditional LED displays require external wiring connections, so after installation, there are usually a lot of scattered wiring on the back, affecting the overall appearance.

However, since all the wiring of hard-wired LED displays is built-in, the back of the display looks neat and orderly, which significantly improves the aesthetics.